Solutions provider for ferrous foundries

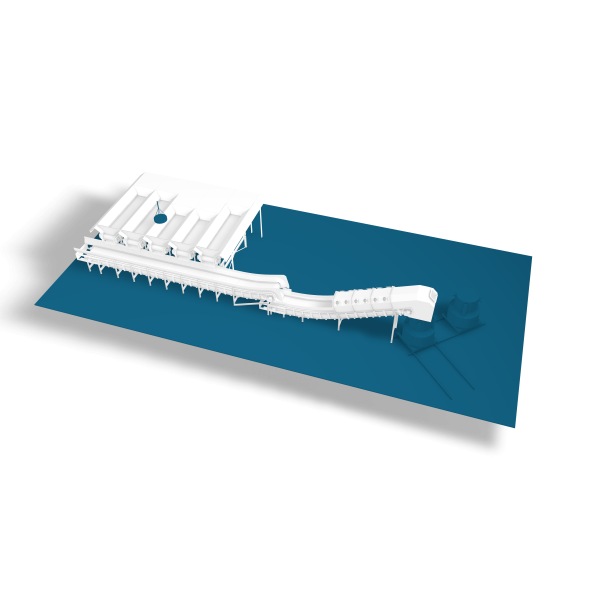

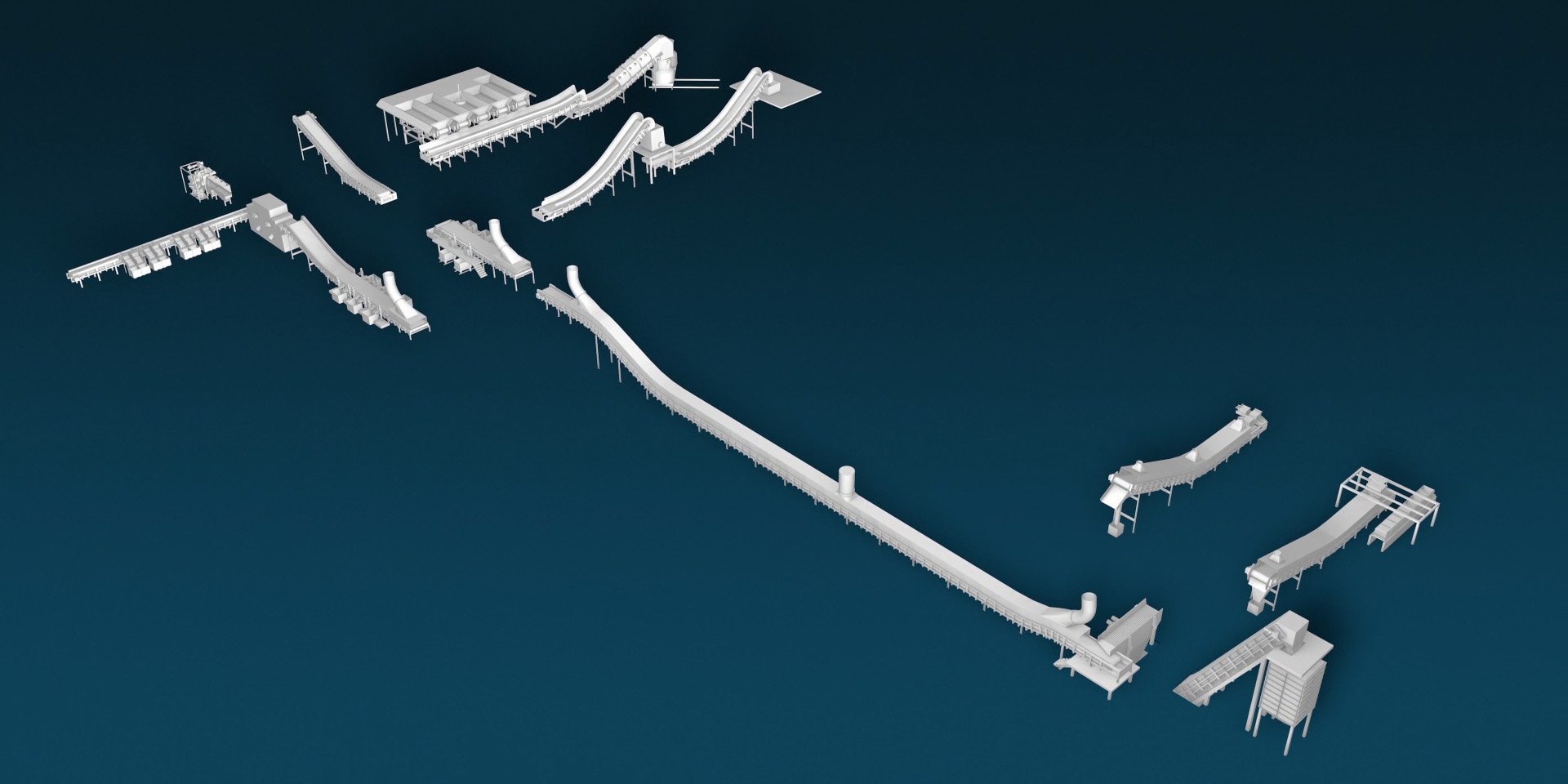

Magaldi foundry equipment can be found scattered throughout the plant as it covers almost all applications.

Whatever the application, Magaldi provides unique solutions featuring a combination of benefits over competing technologies that set them apart from all the others:

- High process reliability & availability

- Class-leading performance

- Flexibility to integrate with existing equipment

- Greater process efficiency

- Minimum energy consumption

- Very quiet operation

- Negligible wear and no tear

- Low maintenance

- Low O&M costs

- High environmental standards

- Long service life

- Quick return on investment.

casting sorting

casting sorting

& out-feed

Conveyng

Conveyng

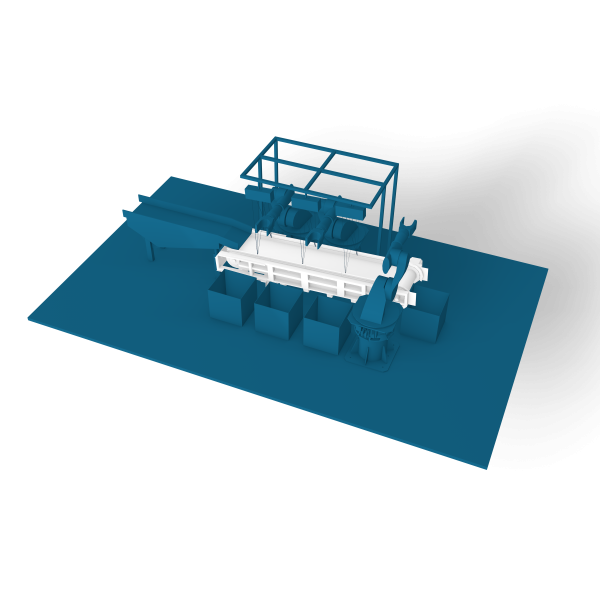

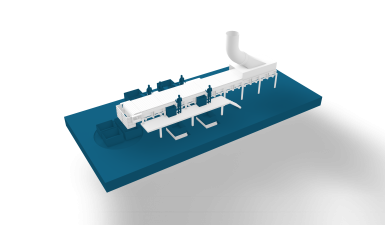

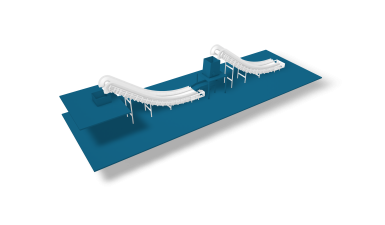

Casting degating & sorting conveyor

Ferrous foundries

The Superbelt® conveyor offers greater safety and ergonomics in carrying out casting degating & sorting operations.

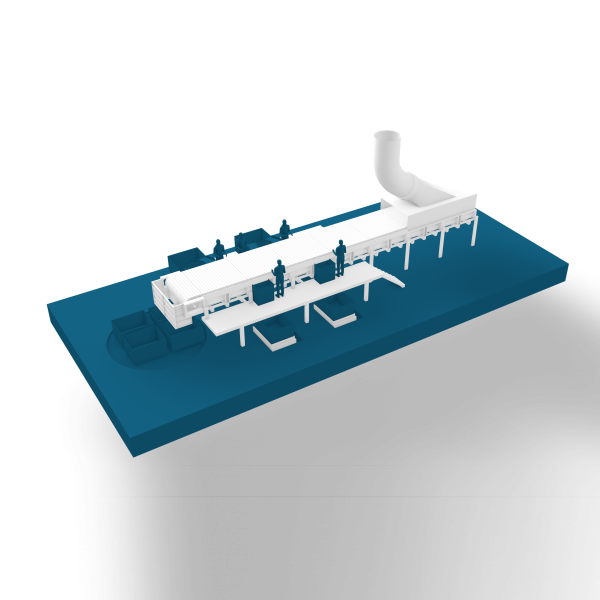

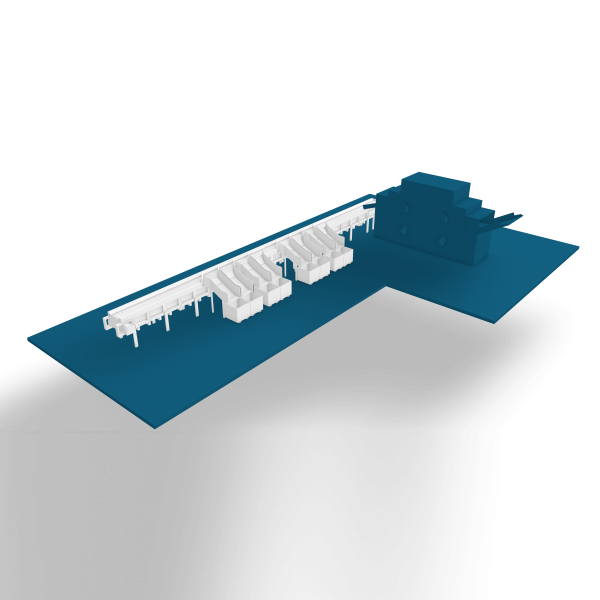

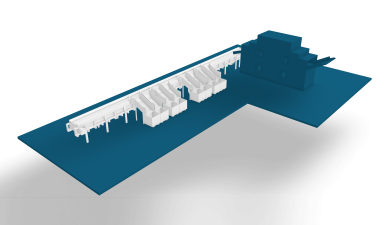

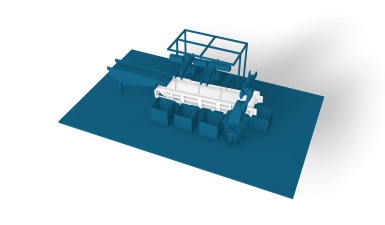

Casting cooler

Ferrous foundries

The Magaldi Casting Cooler (MCC®) allows to efficiently manage the safe transport & controlled cooling of castings.

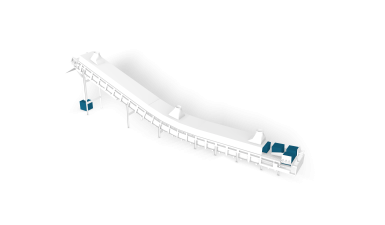

Steel belt conveyor for automatic casting sorting

Ferrous foundries

The unique design of the Superbelt® PRZ conveyors is key to automating casting sorting operations.

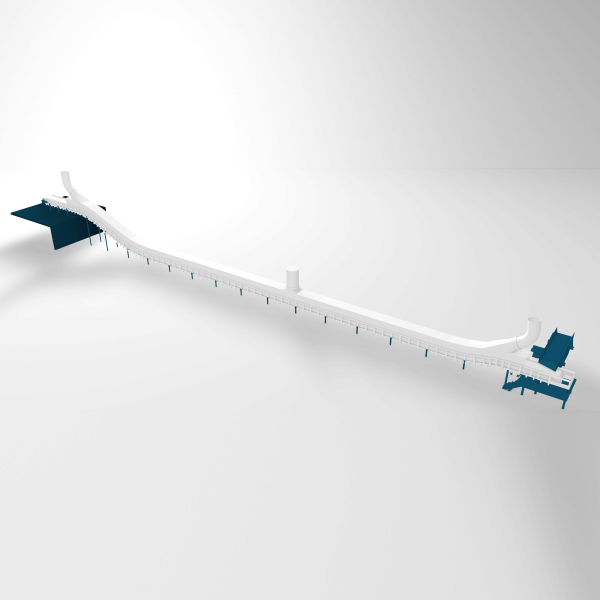

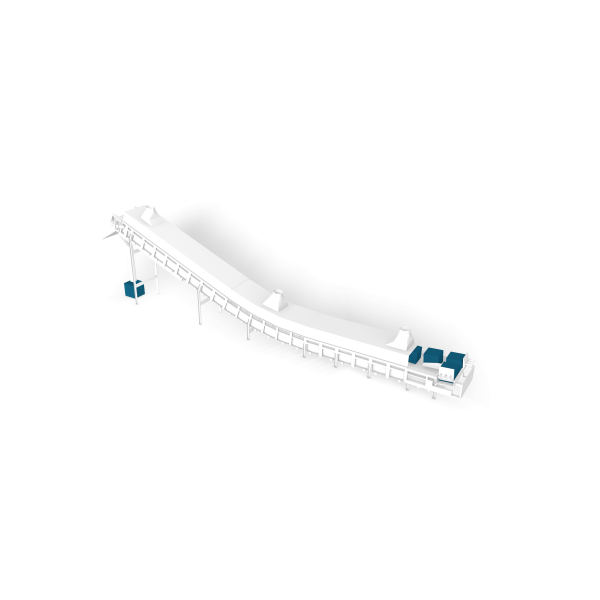

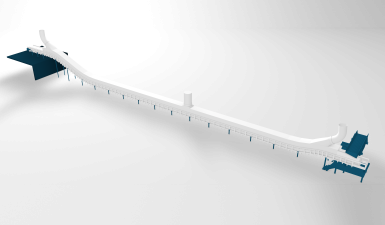

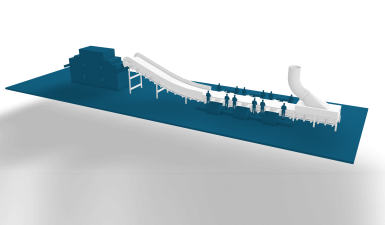

In-mold cooling conveyor

Ferrous foundries

The Superbelt® belt conveyor is a reliable and environmentally friendly alternative to long molding lines used for cooling and transporting the molds from the punch-out to the shakeout

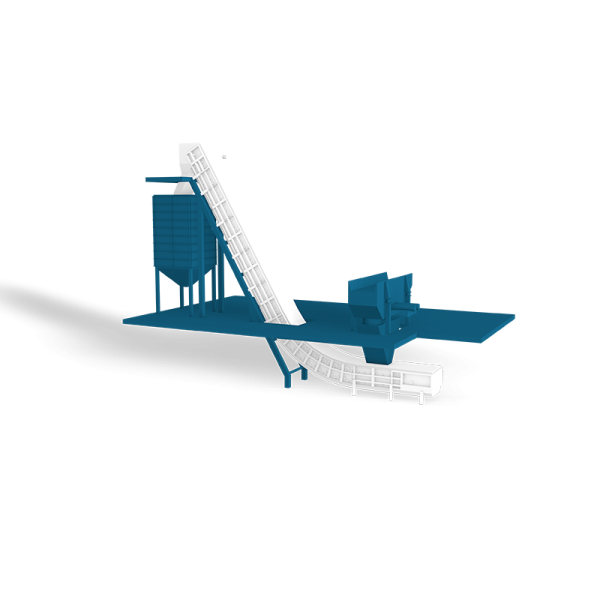

Hot sand conveyor

Ferrous foundries

The Ecobelt® B bucket conveyor is ideal for the safe and spillage-free transport of hot sand.

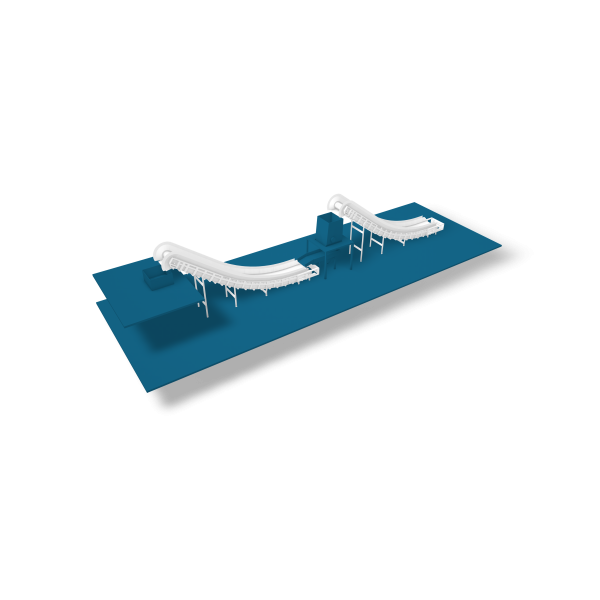

Crusher infeed/outfeed conveyor

Ferrous foundries

Due to the flexible conveyor design, the Superbelt® can be employed as a crusher infeed / out-feed conveyor.

Shot-blast infeed/outfeed conveyor

Ferrous foundries

The Superbelt® conveyor is designed to safely and efficiently move castings to, or away from, the blast area.

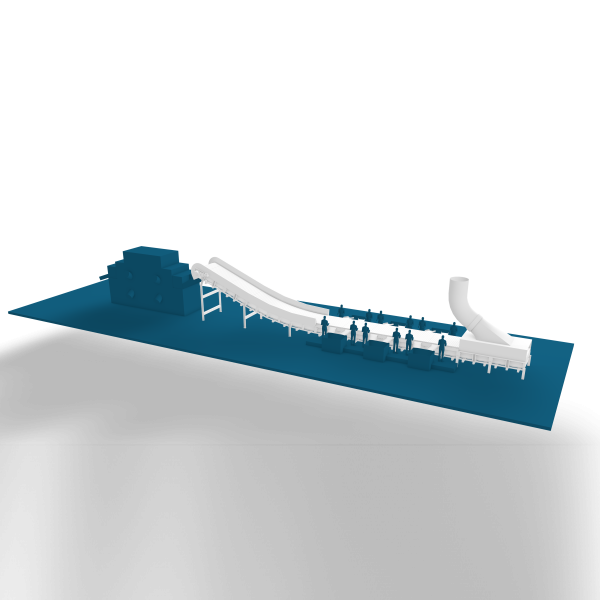

Casting conveyor

Ferrous foundries

The Superbelt® conveyor smoothly moves castings of different sizes, shapes, and weights, even at high temperatures, over long distances, and/or steep inclines, throughout the plant.

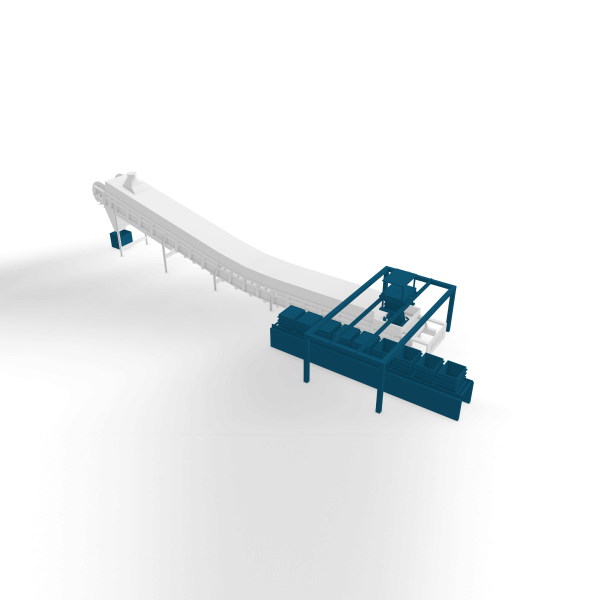

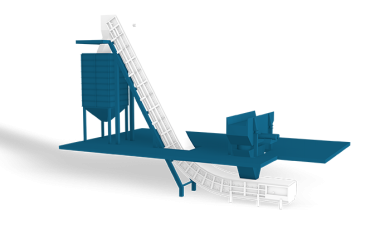

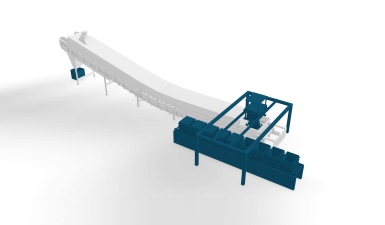

Furnace feeding system

Ferrous foundries

The Superbelt® conveyor allows for transporting metal charges from the scrap storage area to the feeding hopper on the melting deck.

Mold dump conveyor

Ferrous foundries

The Superbelt® conveyor is ideal for transporting the poured molds from the in-mold cooling conveyor or the punch-out station to the shakeout.

Steel belt conveyor for robotic sorting

Ferrous foundries

The Superbelt® conveyor is the ideal solution for the robotic sorting of hot castings.

An installed base of 1,500+ machines and systems worldwide