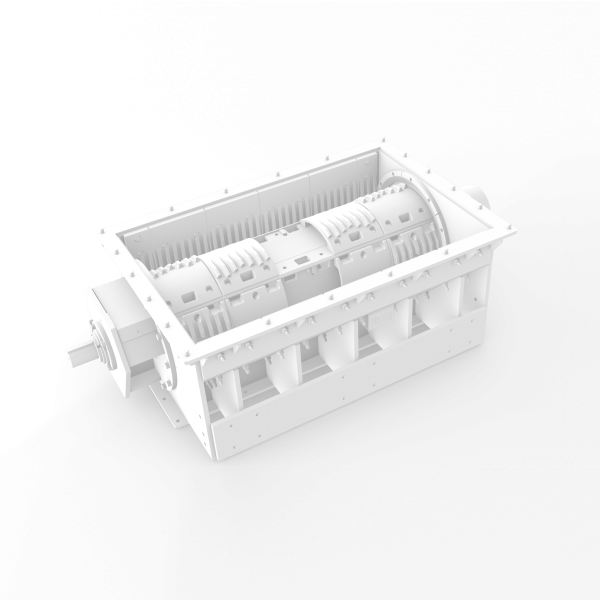

The Magaldi Weigh Belt Feeder

Flexibility where it matters, precision where it counts

Precise weighing and feeding of bulk materials are key for product quality and process efficiency in many different production processes. Although there is a wide range of weighing systems, the most common solution is to use a belt conveyor.

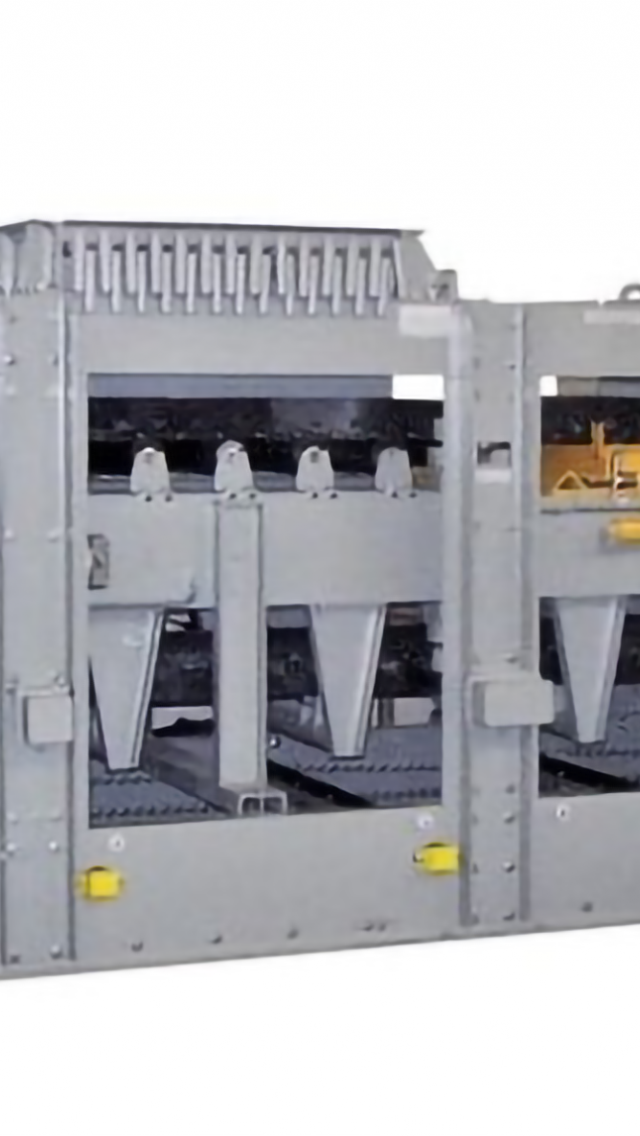

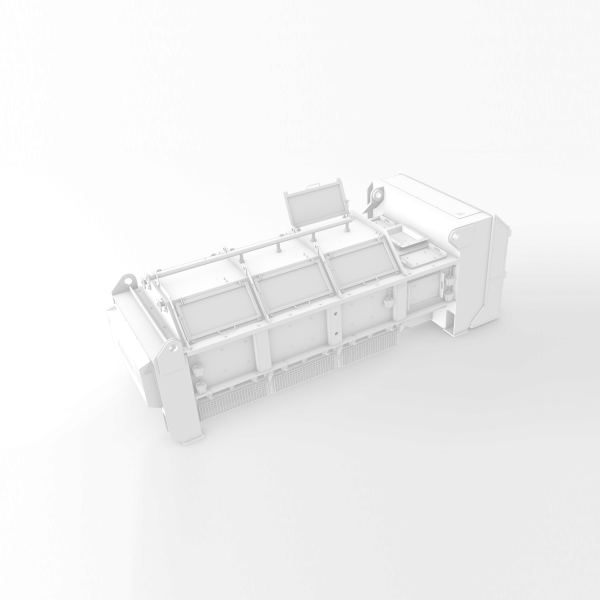

Magaldi developed a belt feeder for severe applications which, thanks to the use of the Superbelt® conveyor, stands out for:

- reliability

- weighing accuracy

- capability to operate under severe conditions (high temperatures, heavy loads, dust contamination, restricted access for maintenance).

The Superbelt® conveyor can be easily transformed into a weigh feeder through load cells installed on the supporting structure of the carrying idlers.

The feed rate is determined by combining the belt speed, monitored by an encoder, and the weight signal, given by the load cells. The controller automatically adjusts the belt speed to maintain the feed rate close to the set point value.

High reliability

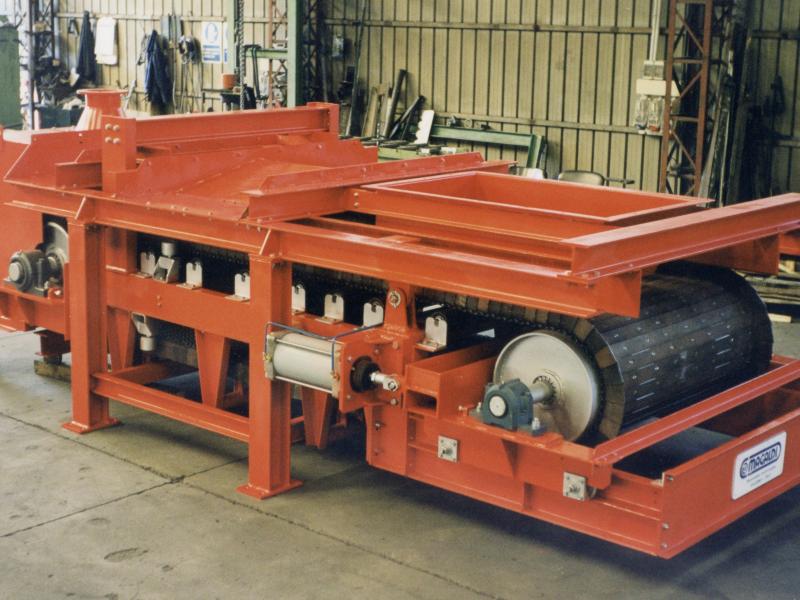

Unlike conventional belt feeders, the Magadi one is much more reliable thanks to the Superbelt® conveyor technology.

The belt damage-tolerant design is based on a multi-link concept: the mesh provides redundancy, little to no maintenance, and trouble-free continuous operation. Even if the mesh gets severely damaged, the conveyor will keep running without sudden failures until the scheduled maintenance.

Also, the patented method of connecting the pans to the mesh belt leaves all components free to expand in any direction without permanent deformations. The pneumatic take-up device automatically compensates for thermal expansions. The result is the conveyor's ability to withstand temperatures up to 1,100°C.

The Magaldi belt feeder also features a solid mechanical structure conceived to ensure maximum strength and resistance to heavy loads, dust, and slag contamination.

High precision weighing

The Magaldi weigh belt feeder ensures a weighing accuracy in the range of ± 1-2% and provides reliable information about the exact weight of transported materials, which is crucial to gaining a better understanding and control of the production process and identifying potential improvements.

Negligible wear

The Magaldi weigh belt feeder withstands harsh environmental conditions without any aging. The absence of sliding friction among the moving parts minimizes equipment wear, even in the case of transporting high abrasive materials.

Reduced dust emissions &

low noise level

The smooth running without vibrations minimizes dust generation while the steel casing prevents any spillage into the environment. Along with a noise level below 75 dB(A), this results in a safer and healthier workplace and allows for overcoming many threats to profitability including housekeeping costs, risk of injuries, and increased unexpected downtime.

Low maintenance requirements

Difficult access to equipment and fast production rates dictate minimum time windows for maintenance, inspection, and repair. For such reason, Magaldi has designed a weighing system that works virtually maintenance-free for many years.

As there are no chains or sprockets, the only points requiring lubrication are the head and tail pulley bearings. The other components are designed for continuous operation and can be checked during preventive maintenance over a multi-year schedule.

Extra long service life

The Magaldi weigh belt feeder is backed with a 3 to 5 years warranty, but its expected lifespan is longer.

Just think that a Magaldi weigh feeder installed in a cement plant in Sardinia (Italy) has been operating since 1981 with the original belt. In its 40+ years of operation, the machine has handled 33.600.000 tons/h of abrasive material without ever requiring belt replacement.