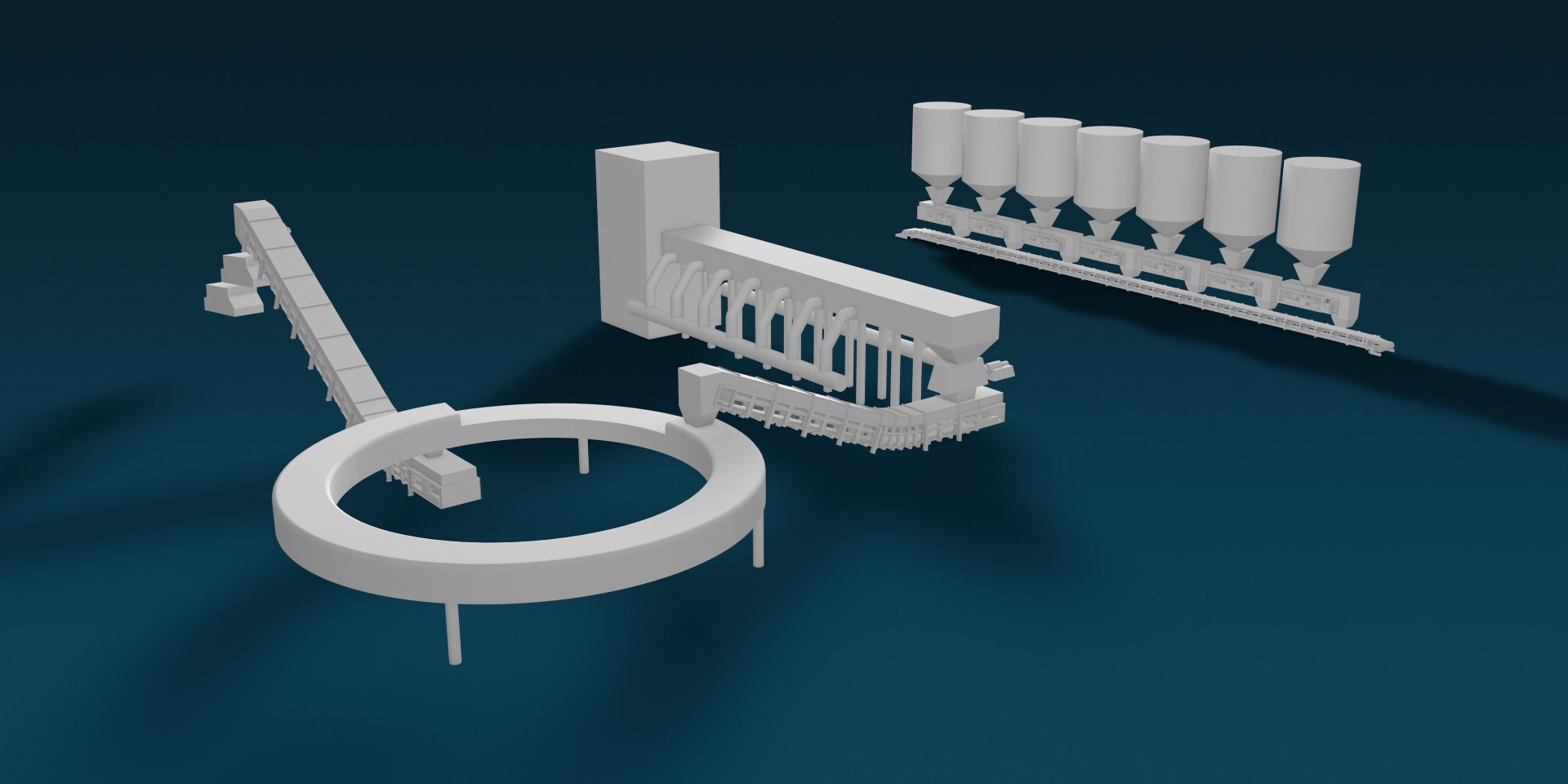

Solutions provider for sinter plants

The extensive know-how in transporting abrasive material at extremely high temperatures has paved the way for the development of custom-tailored solutions to face the challenge of economically and environmentally sustainable production of high-quality sinter.

Magaldi participates in the sintering process both on the raw material side and in the handling of hot sinter, thanks to state-of-art conveyors that combine the capability to handle dusty and abrasive materials, even at high temperatures, and the aptitude for high-quality standards. The result is a combination of benefits over competing technologies that set us apart from all the others:

- High reliability

- Increased uptime

- Class-leading performance

- Greater process streamlining

- Higher quality sinter

- Outstanding energy savings

- Low O&M costs

- Low noise emissions

- Safe operations

- Environmental sustainability

- Long service life.

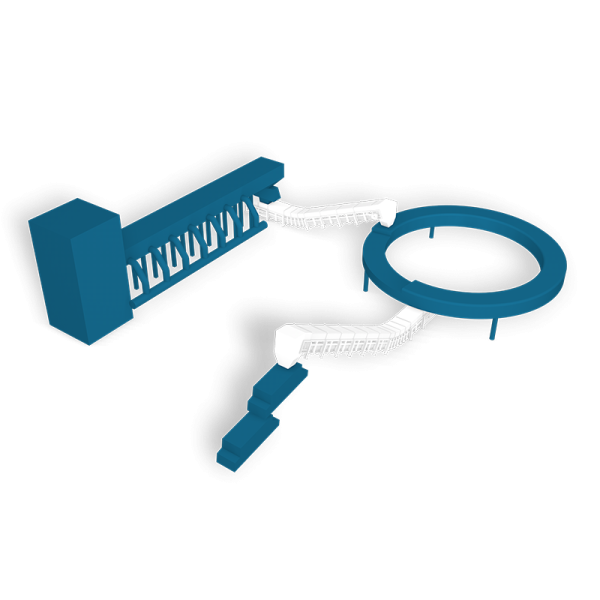

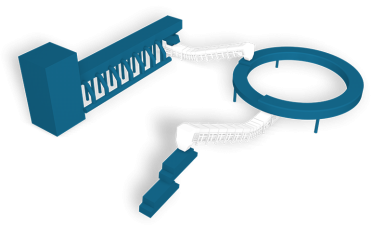

Hot sinter material conveyor

Sinter plants

The Ecobelt® conveyor handles hot, abrasive, and dusty materials such as the sinter mix both in steel plants and in mineral reduction processes (primary smelting).

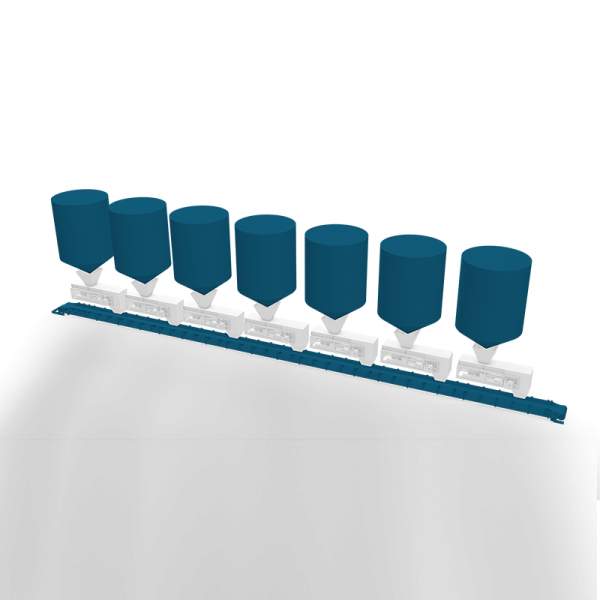

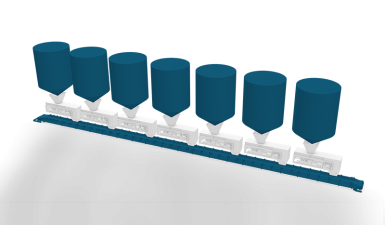

Weigh belt feeder for raw sinter mix

Sinter plants

The Magaldi Weigh Belt Feeders are used for continuous dosing and feeding of charge components.

An installed base of 1,500+ machines and systems worldwide