Solutions provider for the steel industry

Designed to work seamlessly in harsh operating environments, Magaldi heavy-duty conveyors are successfully and reliably used in a wide range of applications in steel mills and scrap metal processing plants.

Convey, feed, unload, dump, and weigh are just some of the tasks Magaldi steel belt conveyors are called upon to perform in the steel industry.

They offer a combination of benefits over traditional technologies that set them apart from all the others:

- High process reliability & availability

- Class-leading performance

- Increase in productivity

- Greater process control

- Safe operations

- Minimum energy consumption

- Very quiet operation

- Negligible wear and no tear

- Low maintenance

- Low O&M costs

- High environmental standards

- Long service life.

Scrap processing area

Melting area

Ladle slag area

Rolling mills area

Mill scale conveyor

Steelmaking plants

The Superbelt® conveyor allows transporting the "red rain" without generating much of fines and reducing power requirements.

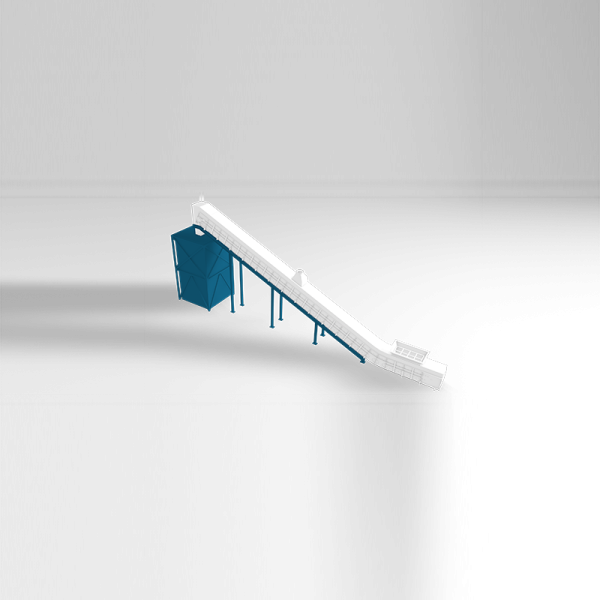

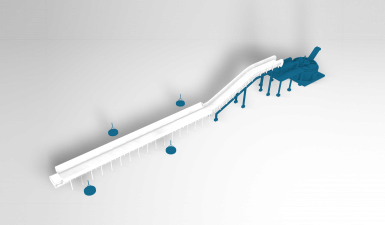

Shear scrap conveyor

Steelmaking plants

The Superbelt® conveyor handles a variety of shear scrap, meeting the severe conditions found underneath shears.

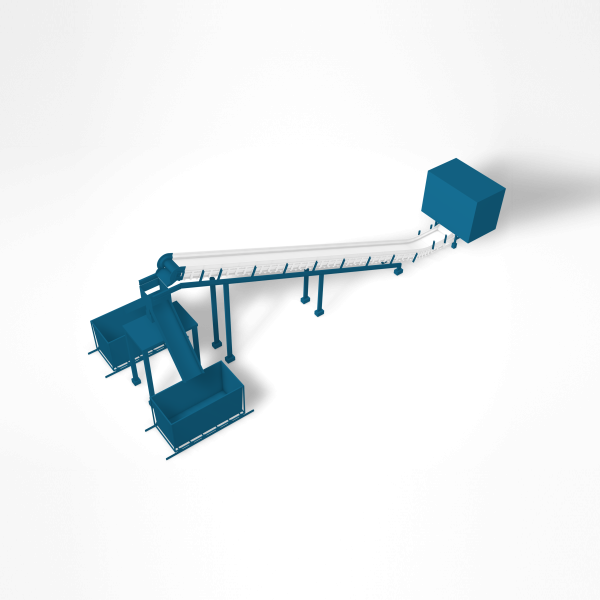

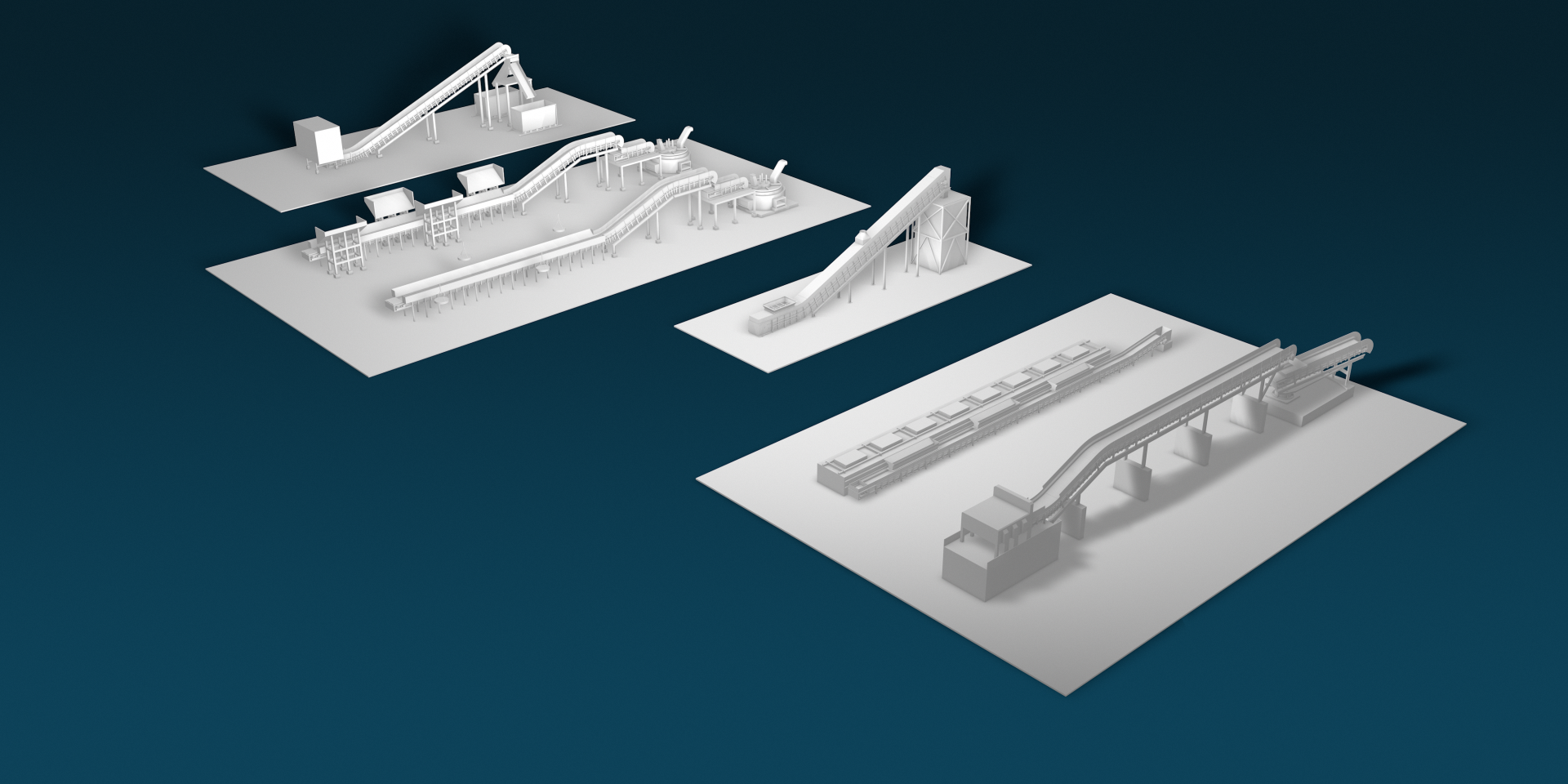

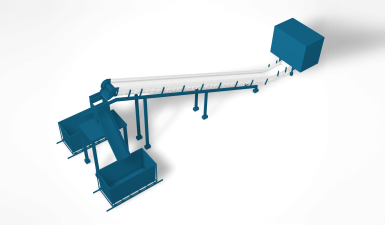

Heavy scrap conveyor for Scrap Sorting and Preparation

Steelmaking plants

The Superbelt® HD conveyor automates the scrap handling process before, during, and after the separation and treatment process.

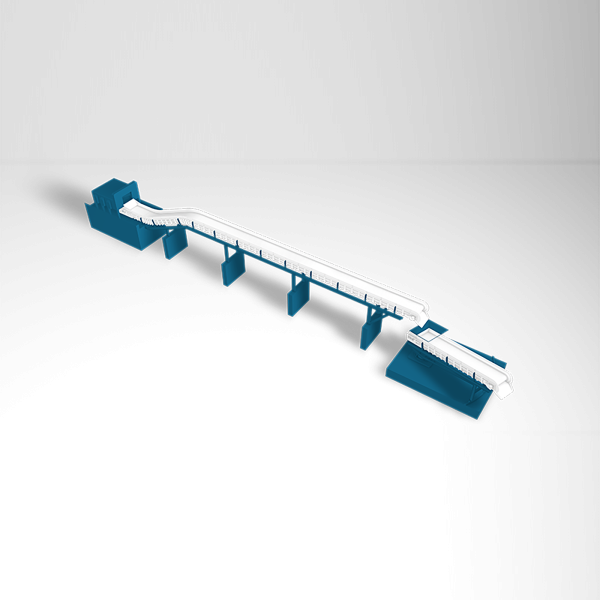

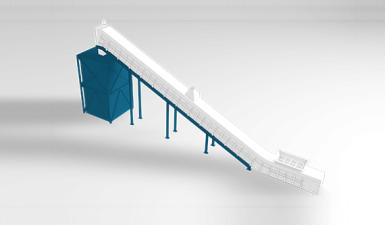

EAF scrap infeed conveyor systems

Steelmaking plants

The Superbelt® HD conveyor continuously transports the scrap charge to the EAF/smelter reliably and safely.

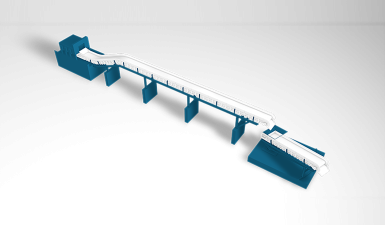

Ladle slag conveyor

Steelmaking plants

The Ecobelt® conveyor provides effective dust containment while safely transporting the white slag.

An installed base of 1,500+ machines and systems worldwide