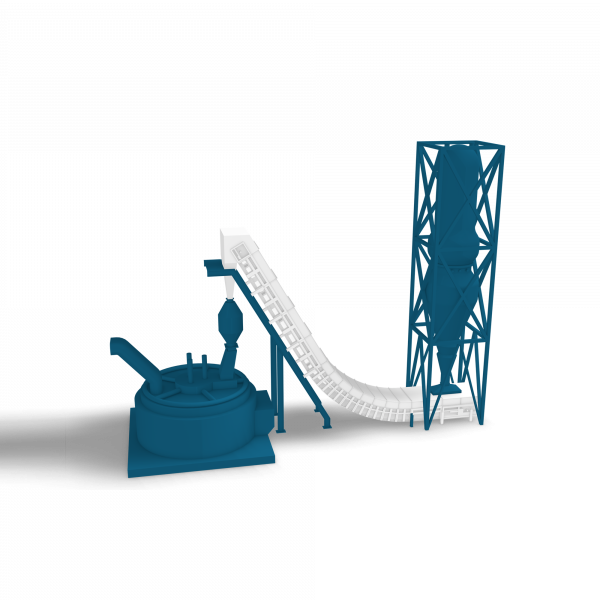

The Ecobelt® HBI cooling conveyor system

Efficient cooling and safe transport of hot briquettes

Hot briquetted iron (HBI) has become a critical component in the environmental strategies of traditional integrated steelworks, as well as a valuable byproduct for Electric Arc Furnace (EAF) steelmakers for their captive direct reduction plants.

HBI can be used as an alternative to scrap to produce high-quality steel or in combination with lower-grade scrap.

Typically, Hot Direct Reduced Iron (HDRI) is transferred from the DRI furnace to briquetting machines where it is formed into HBI. The briquettes are then water-cooled and screened before being transported to stockyards or shipped overseas to steel mills. However, conventional flooded cooling conveyors consume large amounts of water and often fail to cool the briquettes adequately.

An alternative approach to HBI cooling is based on the use of a collector chain belt conveyor that cools briquettes with vaporized water. While innovative, these methods have notable drawbacks. Chains, wheels, and sprockets are vulnerable to heat, fines, and moisture, which can undermine the system's reliability.

The Ecobelt® HBI cooling conveyor system effectively addresses the challenges of hot briquette cooling with several advanced features.

High reliability

The sealed design protects sensitive components - such as bearings and drive and mechanisms – from the harsh internal environment, presenting heat, steam, water, and fines, thereby enhancing overall system reliability.

Durability & Redundancy

The conveyor features steel pans connected to a patented double-wire mesh, which provides redundancy. Even in the event of severe damage, the conveyor will continue to operate until scheduled maintenance, ensuring uptime and productivity.

High Temperature Resistance

HBI exits the briquetting machines at approximately 700 °C. Unlike traditional chain conveyors, which suffer from high temperatures, the Ecobelt® HBI can transport materials up to 1,100 °C thanks to a patented method of connecting the pans to the mesh belt that accommodates thermal expansion without permanent deformation.

Effective cooling

Briquettes are slowly cooled from over 700°C to less than 100°C, allowing safe handling by downstream equipment, particularly rubber belt conveyors. The slow cooling process results in superior-quality briquettes, which typically have greater strength and less breakage. This means that there is a greater number of briquettes that remain whole during handling, storage, and shipping.

No re-oxidation

Because HBI is highly reactive at high temperatures and tends to re-oxidize when exposed to air, the Ecobelt® HBI conveyor incorporates an inert gas system. The gas purge (like nitrogen) creates an inert atmosphere throughout the conveyor. This minimizes the risk of re-oxidation and ensures no metal loss during transport.

Dust Control & Low Spillage

Smaller fines are considered detrimental for several reasons, which include handling difficulty, increased losses due to conveyor in off-gas, and increased segregation of fractions leading to bridging/plugging. With the Ecobelt® HBI, the smooth transport and absence of relative movement between the material and the steel pans ensures less fines generation during handling. Additionally, the enclosed design prevents material spillage, enhancing environmental safety.

Low maintenance requirements

With no critical components like chains or sprockets, maintenance is streamlined. Only the head and tail pulley bearings and return idler bearings require lubrication, while upper idlers and rollers are designed for lifetime lubrication. This allows for a multi-year preventive maintenance schedule, reducing downtime and operating costs.