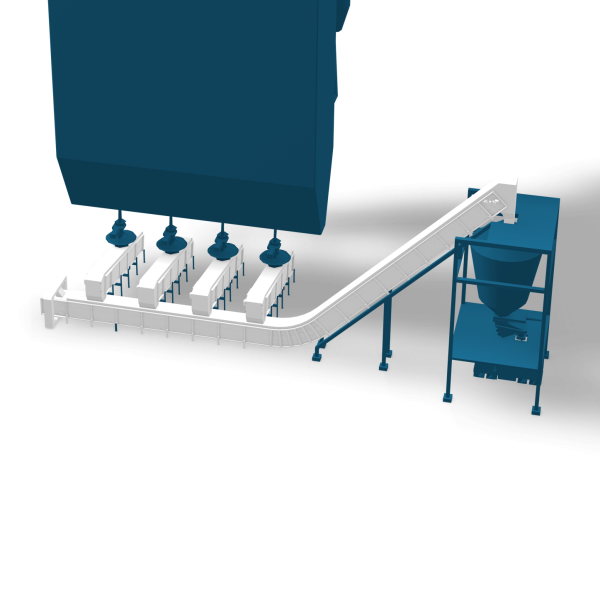

The Ecobelt® FA system

A reliable solution to mechanically convey fly ash from the collection hoppers to the storage silos

Fly ash handling is an essential process in any coal-fired power plant due to ever-tightening environmental regulations and the need to maintain general plant efficiency.

However, the fly ash properties (fine particle size, frictional and abrasive nature, high temperature) make them hard to handle.

Mechanical vs. Pneumatic system

Commonly used to transfer fly ash from the collection hoppers to the storage silos, pneumatic conveying systems often encounter problems with insufficient conveying capacities, plugging, erosive wear in elbows, and build-up in the line.

In contrast, the Ecobelt® FA system is the advisable solution to secure continuous fly ash transport from the hoppers located along the flue gas path, including the economizer (ECO), the selective catalytic reactor (SCR), air heaters (AH), and electrostatic precipitator (ESP) or baghouse.

In case of layout constraints or if final storage silos are far from the boiler area, the Ecobelt® FA can be associated with a pneumatic system that moves fly ash from the temporary silo to the final one, thus combining the advantages of mechanical transport in the critical extraction area with a pneumatic transport from a single point.

Reduced risks of blockage in the collection hopper

Frequent choking of the conveying lines due to coarse ash is observed in vacuum or pressurized pneumatic systems, resulting in increased conveying time and high hopper levels. Also, with these systems, it is still not uncommon to encounter arching (also known as bridging) problems due to their discontinuous operation and the hopper’s outlet cross-section being restricted by the pneumatic system’s ash intake valve.

With the Ecobelt® FA conveyor system, risks for ash choking and cohesive arching are mitigated since it is installed under each row of collection hoppers and continuously receives the ash from the hoppers, which are therefore empty. Furthermore, the hoppers can be provided with an enlarged (up to 7 times more) outlet cross-section, allowing a smooth mass flow discharge.

Coarse particles transport

Agglomerated lumps of fly ash and foreign materials removed from the hoppers under the ECO, SCR, and AH can create flow problems. Because of the elevated gas temperatures in the hoppers, the coarse particles (known as “popcorn ash”) tend to sinter and become difficult to remove through pneumatic conveying systems.

The Ecobelt® FA conveyor smoothly transports even the largest and heaviest lumps thanks to the well-proven Superbelt® (steel belt), running at low speed and without friction between fly ash and metal parts.

The Superbelt® is the key to reliable system performance. It is a steel belt made of a double-wire mesh with partially overlapped steel pans bolted on and supported by carrying idlers over its entire width. The driving force is transmitted by friction between the head pulley and the mesh belt while a pneumatic take-up device on the tail pulley provides constant tension. Its unique design allows for conveying high-temperature ashes and withstanding extreme conditions.

Negligible wear &

No tear issues

The presence of a significant portion of silicon dioxide makes fly ash very frictional and abrasive. As a result, pneumatic conveying lines undergo tremendous pipeline wear issues, resulting in the need for frequent replacement.

In contrast, with the Ecobelt® FA system, fly ash is mechanically conveyed without friction between ash and metal parts. Equipment wear is therefore negligible, and also horsepower requirements are minimum.